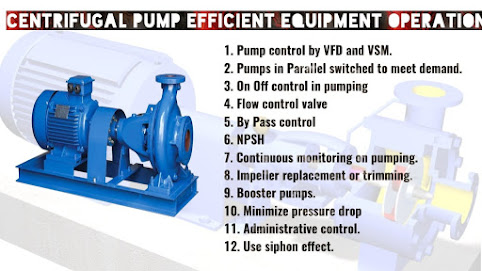

Centrifugal Pump Efficient Equipment Operation blog contains power optimization in pumping by following way

1. Pump control by VFD and VSM is always efficient than

Discharge control valve.

2. Pumps in Parallel switched to meet demand.

3. On Off control in pumping

4. Flow control valve

5. By Pass control

6. Ensure adequate NPSH of pumping system.

7. Continuous monitoring on pumping.

8. Impeller replacement by smaller or trimming should be

placed in the case of discharge valve throttling.

9. For Small loads with high

pressure requirement boosted pumps are required.

10. For Heat exchangers

Maximize temperature difference so minimize flow requirement. Heat exchanger

bypass system should be placed in the case of exceed temperature difference.

11. In continuous system over

flow line is connected to step back tanks. Maintain levels around 95% so double

pumping avoided.

12. Avoid pumping with free

fall effect use siphon effect for beneficial effect.

13. Frequent Inspection and Preventive maintenance.

14. Line sizing of circulation line.

15. Pump should be operated near BEP : Best Efficiency Operation.

1. Pump control by VFD and VSM is always efficient than Discharge control valve.

Highlights- It is gives lower power consumption.

- Lower speed creates lower pressure on impeller and other internal parts.

- Lowering shaft stress, bearing load, vibration and noise in pumping.

- Increases pump seal and bearing life.

- Increasing life of piping and installations, Instruments.

- Bearing life is inversely proportional to 7th power of speed

Pump discharge valve must be fully open, if pump discharge valve is in partially closed condition [throttled] then lower pump size should be installed Impeller must be trimmed. If possible Variable frequency drive must be installed.

VFD : Variable Frequency Drive is speed adjustment by controlling its Frequency of power.

VSM : Variable Speed Motor has winding function which is operating in 25% 50% 75% and 100% Generally found in Reciprocating Compressor.

Read more :

VFD : Variable Frequency Drive

VSM : Variable Speed Motor

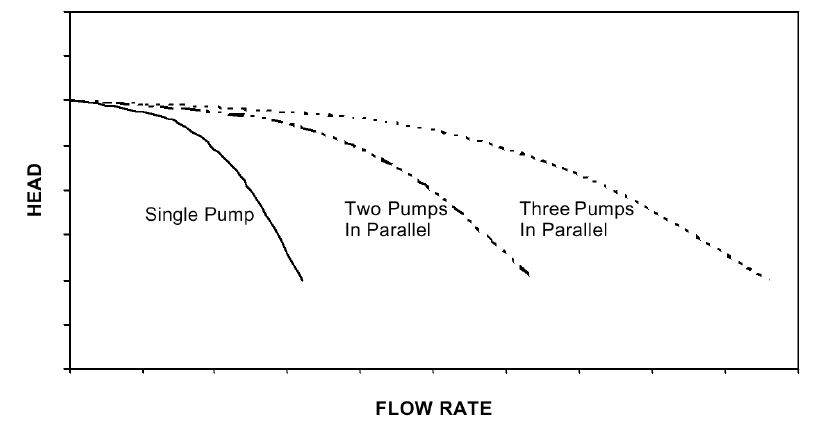

2. Pumps in Parallel switched to meet demand.

Parallel pumping is efficient in following case

System 1 : High Static Head loss system

System with high static head loss and parallel pumps are installed.

Variation in flow is occur and for limited time flow is higher is required.

Continuous operation will increase energy consumption

System 2 : Static head loss + Friction loss system

System curve is not affected when combine loss of Static head loss and Friction head loss.

In combine loss system it will result in Higher head and less flow rate per pump.

If we double pump in operation will not double the flow.

It is possible to operate Small pump with bigger pump but the condition is they have same Discharge pressure and Head.

3. On Off control in pumping

On Off control should be installed in following systems

A. Continuous fluid dosing system.

If there is a system which has pressure is equal to atmospheric pressure and fluids are dosing with dosing pump.

Dosing pump is not required in this system.

For this type of system Elevated tanks [ Head Tank ] is best option. From this tank dosing is energy free operation.

Pumping is only required when head tank level is low.

Pumping cost and pump maintenance cost is prevented by this system

B. Batch Processes