Cooling tower classification

Classification by build

Package Type

Field Erected Type

Classification based on heat transfer method

Wet Cooling Tower

Dry Cooling Tower

Fluid Cooler

Classification based on air draft

Atmospheric Tower

Natural Draft Tower

Mechanical Draft Cooling Tower

Classification based on air flow pattern

Cross flow

Counter flow

Air might enter the tower driven by a density gradient (natural draft), might be pushed into the tower (forced draft) at the base or drawn into the tower (induced draft) assisted by a fan. Several types of cooling towers have been designed on the basis of the above factors and operating strategies.

The cooling tower might be classified into several types, but they are broadly categorized by following considerations:

1. Whether there is direct or indirect contact

2. The mechanism used to provide the required airflow

3. The relative flow paths of air and water

4. The primary materials of construction

5. the type of heat transfer media applied

6. The tower’s physical shape

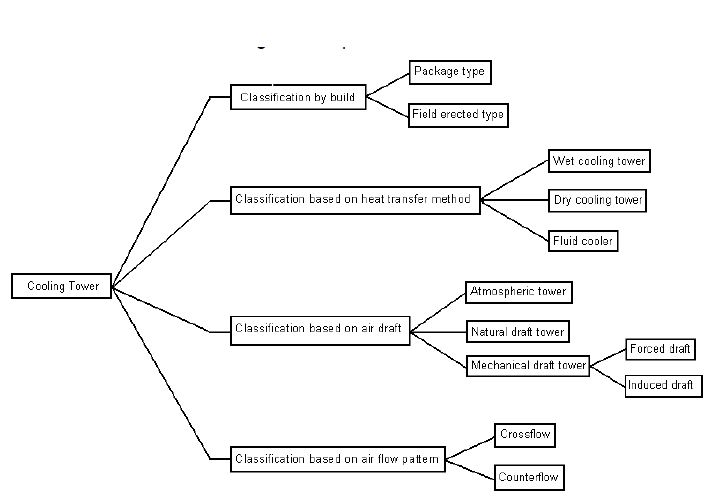

General classification of cooling tower is pictured below:

Classification by build

Package Type

The capacity of package type towers are limited and for that reason, they are usually preferred by facilities with low heat rejection requirements such as food processing plants, textile plants, buildings like hospitals, hotels, malls, chemical processing plants, automotive factories etc.

Due to the intensive use in domestic areas, sound level control is a relatively more important issue for package type cooling towers.

Field Erected Type

These towers are larger in size compared to the package type cooling towers.

Classification based on heat transfer method

Wet Cooling Tower

This type of cooling tower operates based on evaporation principle. The working fluid and the evaporated fluid (usually water) are one and the same. In a wet cooling tower, the warm water can be cooled to a temperature lower than the ambient air dry-bulb temperature, if the air is relatively dry.

Dry Cooling Tower

This tower operates by heat transfer through a surface that separates the working fluid from ambient air, such as in a tube to air heat exchanger, utilizing convective heat transfer. Dry cooling tower does not use evaporation.

Fluid Cooler

This tower passes the working fluid through a tube bundle, upon which clean water is sprayed and a fan-induced draft applied. The resulting heat transfer performance is much closer to that of a wet cooling tower, with the advantage provided by a dry cooler of protecting the working fluid from environmental exposure and contamination.

Classification based on air draft

Atmospheric Tower

An atmospheric tower consist of a big rectangular chamber with two opposite louvered walls. The tower is packed with a suitable tower fill.

Atmospheric air enters the tower through the louvers driven by its own velocity. An atmospheric tower is cheap but inefficient.

Its performance largely depends upon the direction and velocity of wind.

Natural Draft Tower

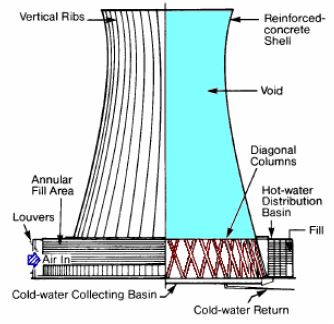

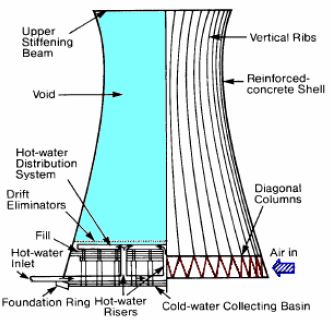

The natural draft or hyperbolic cooling tower makes use of the difference in temperature between the ambient air and the hotter air inside the tower. As hot air moves upwards through the tower (because hot air rises), fresh cool air is drawn into the tower through an air inlet at the bottom.

A natural draft tower is so called because natural flow of air occurs through the tower.

Two factors are responsible for creating the natural draft:

- A rise in temperature and humidity of air in the column reduces its density, and

- The wind velocity at the tower bottom.

Due to the layout of the tower, no fan is required and there is almost no circulation of hot air that could affect the performance. But in some cases, a few fans are installed at the bottom to enhance the air flow rate. This type of tower is called ‘fan-assisted’ natural draft tower.

The hyperbolic shape is made because of the following reasons:

- More packing can be fitted in the bigger area at the bottom of the shell;

- The entering air gets smoothly directed towards the centre because of the shape of the wall, producing a strong upward draft;

- Greater structural strength and stability of the shell is provided by this shape.

The pressure drop across the tower is low and the air velocity above the packing may vary from 1-1.5 m/s. The concrete tower is supported on a set of reinforced concrete columns. Concrete is used for the tower shell with a height of up to 200 m.

These cooling towers are mostly only for large heat duties because large concrete structures are expensive.

Induced draft cooling tower

Classification based on air flow pattern

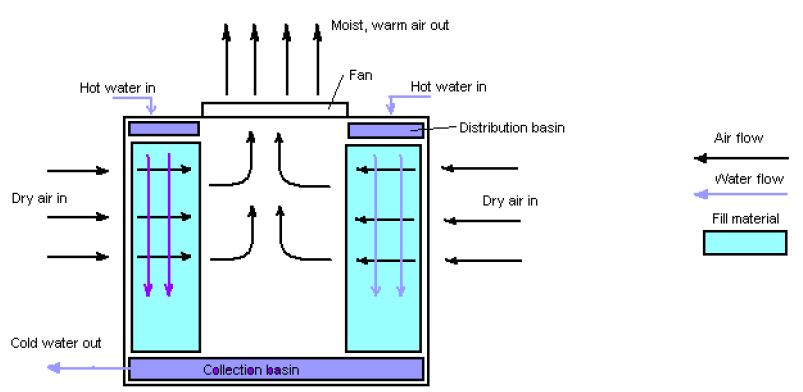

Crossflow

Crossflow is a design in which the air flow is directed perpendicular to the water flow. Air flow enters one or more vertical faces of the cooling tower to meet the fill material.

Water flows (perpendicular to the air) through the fill by gravity. The air continues through the fill and thus past the water flow into an open plenum area.

A distribution or hot water basin consisting of a deep pan with holes or nozzles in the bottom is utilized in a crossflow tower. Gravity distributes the water through the nozzles uniformly across the fill material.

Counterflow

In a counterflow design the air flow is directly opposite to the water flow (see diagram below). Air flow first enters an open area beneath the fill media and is then drawn up vertically. The water is sprayed through pressurized nozzles and flows downward through the fill, opposite to the air flow.