Different Types of valves uses in different sectors.

In this article mentioned 19 types of valves

1. Globe valve

2. Gate valve

3. Ball valve

4. Butterfly valve

5. Diaphragm valve

6. Plug valve

7. Needle valve

8. Angle valve

9. Pinch valve

10. Slide valve

11. Flush bottom valve

12. Solenoid valve

13. Control Valve

14. Flow regulating valve

15. Back pressure regulating valve

16. Y-type valve

17. Piston valve

18. Pressure regulating valve

19. Check valve

1. Globe valve

It operates by reciprocating action of disc or plug. The disc or plug moves to or away from the seat thereby stopping the fluid flow or allowing the fluid to flow. The disc or plug seats over the valve seat.

The valve seat can be removable.

The stream flows upward generally, except for vacuum service. Pressure drop in the globe valve is high.

Application: Globe valve used to regulate fluid flow for throttling purpose.

2. Gate valve

Gate valve functions by the reciprocating action of disc in its body. It can have a single disc or double disc. In double disc valve shut off is good.

Gate valve can have rising or non-rising stem.

It has good shutoff characteristics. The pressure loss through the valve is minimum.

Application: Gate valves are generally used in systems where low flow resistance for a fully open valve is desired and there is no need to throttle the flow. It is prone to vibration in the partially open state.

3. Ball valve

Ball valve has a spherical plug. The spherical plug is a controlling element.

It is used where throttling and shut off combination is required. It offers good flow characteristics. Ball valve consists of a two way globe and the ball rotates between resilient seats.

Hole in the ball is lesser in diameter then the nominal bore of the pipe.

It is compact and requires low maintenance and no lubrication. One quarter turn of the stem changes the valve from fully closed to completely open.

It is available in venture pattern, reduced and full port patterns. By giving a quarter turn to the ball, the valve can be closed or opened. The valve does not give good throttling.

Conventional ball valves have relatively poor throttling characteristics. In a throttling position , the partially exposed seat rapidly erodes because of the impact of high velocity flow.

4. Butterfly valve

In butterfly valve the controlling element is a disc called as flapper, which rotates in horizontal or vertical direction and allows the fluid to flow.

Butterfly valve is mainly used for lesser pressure drop.

It is economic, easy to install, light in weight , does not allow the solids to build up and required less space..

One quarter turn of the stem changes the valve from fully closed to completely open.

Its operation can be manual, power, or automatic Water type butterfly valve is shown.

Disadvantage: No throttling efficiency. Disk movement is unguided so at turbulence flow it can be damaged.

Application: Butterfly valve is suitable for throttling or on-off operation at low pressure drop.

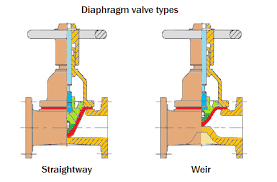

5. Diaphragm valve

Main parts of a diaphragm valve are, body, bonnet and a flexible diaphragm.

Diaphragm is lifted up when the valve is opened and the diaphragm is tightly pressed against the bottom of valve, when it is closed.

Diaphragm valves are classified as:

1. Weir type and

2. Straight through type.

In weir type diaphragm valve relatively low thrust and shut off stroke is required. This gives longer life for diaphragm. Weir type diaphragm valve is commonly used.

Straight through type diaphragm valve is suitable for handling slurries, viscous liquids, fibrous suspensions.

In some diaphragm valves, the diaphragm is not fully lifted up of the weir, so accurate control of small flow becomes possible. Diaphragm is made either from rubber, neoprene or buna.

It is avalable in size 3 mm to as large as 600 mm. It can be used up to 20 kg/cm2 pressure and 2200 C temperature.

Material of construction for diaphragm valve can be cast iron, stainless steel, and corrosion resistant alloys.

6. Plug valve

Plug valve is used for on-off service. It is the oldest type of valve. The main parts of a valve are body, plug and cover. Plug can be cylindrical or tapered.

The plug has a slit cut in it to allow the fluid to flow. It provides a straight line and can be opened or closed just by giving a quarter turn.

Plug valve can be made to have one or more openings to change the direction of flow. It can be lubricated or non-lubricated type.

Plug valves have the advantages such as quick action, easy operation, minimum space for installation, light in weight and high capacity. It can be used for slurry handling and pulp handling. Valves with spherical plug are useful in automatic process control operations.

Plug valve can be fabricated from cast iron, stainless steel, copper, alloys, nickel alloys and other corrosion resistant alloys. Tapered plug valve without lubrication is shown.

Lubricated plug valve is used in oil industry while non-lubricated valve is preferred where contamination is to be avoided.7. Needle valve

8. Angle valve

It is similar to globe valve. In angle valve the inlet and outlet ends are at 900 to each other.

The axis of the stem is in line with one of the ends. Angle valve gives lower pressure drop and less pipe fittings in the piping system. Angle valves can be used for corrosive fluids. It can have a single body or split body.

9. Pinch valve

It can be used for on-off and throttling operations. The valve has a sleeve which is replaceable.

The valve is operating on principal relies on flexible section of pipe being flattened between two moving bars.

When both bars came together flow is reduced.

It has low maintenance cost, low pressure drop and low initial cost. It can be used for handing slurries. Its operation mechanism is completely isolated from fluid.

This eliminates problems of corrosion and contamination.

Sleeves can be made of rubber or plastic. Pinch valve can be designed for pressures up to 20 kg/cm2, and temperature up to 250°C. Pinch valve is not suitable for vacuum operation.

10. Slide valve ( Knife valve, Knife gate valve)

It is used for controlling low pressure flow of gases, liquids, suspensions and fluidized solids. It has two parallel body seats between which the disc slides.

Slide valve should never use for throttling purposes. If valve throttle frequently then base may mis align which may result in pass.

The disc acts as a gate, Pressure chop offered by slide valve is very low.

It is available in size ranging from 50 mm to as large as 1500 mm.

It can be used for pressures Up to 25 kg/cm2 and temperature up to 650°C.

11. Flush bottom valve

12. Solenoid valve

It is a control valve. Solenoid is applied to sliding stem, on-off globe valves.

It is used for emergency shut off service requirements. It is available in size ranging from 1 mm to 100 mm.

It can be used for absolute vacuum to very high pressures in the range of 650 kg/cm2 and temperatures as low as-250°C to 800°C.

Material of construction for solenoid valve can be cast, iron, stainless steel, aluminum, plastic brass etc. Solenoid valves find wide applications in cryogenic operations.

14. Flow regulating valve

Flow regulating valve: In a flow regulating valve a constant flow rate is maintained irrespective of any changes in the line pressure.

As the pressure changes on either side of the stream, the diaphragm actuates a spring loaded valve. The spring loaded valve opens or closes maintains the flow at constant rate.

15. Back pressure regulating valve

Back pressure regulating valve: It has a spring loaded disk or piston.

The disc or piston lifts up and opens the valve whenever the pressure in the system exceeds the pressure exerted by the spring.

A diaphragm transmits the pressure to the disc or piston. It has a design similar to relief valve.

16. Y-type valve

Y-type valve: In this valve the orifice is approximately at 42 to the path of flow. Y-type valve

offers low pressure drop and good throttling condition.

17. Piston valve

Piston valve: It is used for hydraulic systems, air pressure control etc

18. Pressure regulating valve

Pressure regulating valve: It is used for regulating steam pressure if it exceeds the desired level.

19. Check valve

Check valve: There are three types of check valves:

A. Swing check valve B. Piston check valve C. Lift check valve

It is used to prevent flow reversal. Fluid pressure keeps the valve open. It is closed either by back pressure of fluid or by weight of the check system.

A. Swing check valve: is used for low fluid velocities and where flow reversal is not frequent. Swing check valve can be used on the discharge side of pressure relief valve.

B. In lift check valve: a disc, piston or a ball is used as a checking device. It can be installed in horizontal or vertical position.

The fluid pressure raises or closes the disc or ball. Lift check valves are suitable where pressure drops are high. It is suitable for small pipelines.

C. Piston check valve: is stem operated. It can be operated manually or by a motor. Check valves are available in sizes ranging from 6mm to 600 mm.

They can be used for pressures upto 170 kg/cm2 and temperatures upto 675°C. Material of construction for check valve can be cast iron, steel, ductile iron, and corrosion resistant alloys.

Trouble shooting

Problem: Valve leaking or not closing properly

Causes: Corrosion, Flange or flange bolt failure. Wear fail, foreign material stuck

Actions: Attempt to flush, Valve remove and clear, replace valve.