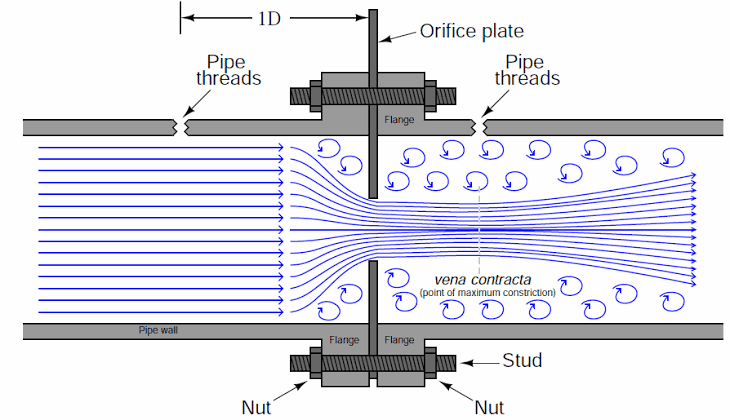

An orifice meter is consists a thin plate with a bore on the plate. This plate acts as a restriction. Pressure taps are provided before and after the orifice plate in order to measure the drop in pressure.

Working

In the Venturi meter; when the fluid reaches the converging part then according to continuity equation, when the cross sectional area decreases then the velocity of the flowing fluid increases.

Bernoulli’s equation says that when the velocity of the flowing fluid increases the pressure of the flowing fluid decreases.

This drop in pressure is used to calculate the average velocity or flow rate of the flowing fluid. The fluid then passes through the diverging section which is responsible for pressure recovery.

In the Orifice Meter; the flowing fluid starts to converge before it reaches the orifice plate and it continues to converge after passing through the orifice plate until a point called vena contracta is reached.

The vena contracta is the point of maximum velocity and minimum pressure in the flow system.

Principles of continuity equation and Bernoulli’s equation are applied here also in order to determine the average velocity and flow rate of the flowing fluid.

When both side of Orifice connected to Differential Pressure Coil then it shows digital value on DCS or Panel

Pressure loss

In Venturi meter; there is a specific part called diverging section which is responsible for recovering the lost pressure which was affected due to the measurement of the average velocity or flow rate of the flowing fluid.

The pressure loss is about ten percentages (10%).

In Orifice meter; the pressure loss is relatively more compared to Venturi meter because it contains no specific part which is aimed for pressure recovery. The pressure loss is fifty to sixty percentages (50-60%).

Coefficient of Discharge

The Coefficient of Discharge is the ratio between the actual discharge measured by experiments and theoretical discharge calculated by equations.

In Venturi meter; the value of coefficient of discharge can be up to 0.98, it is relatively high.

In Orifice meter; the value of coefficient of discharge is in the neighborhood of 0.6, it is relatively low.

Types of Orifice Meter

Concentric orifice plate: Most commonly used

Segmental & Eccentric orifice plate: Used for fluids containing suspended solids.

Tappings for the Orifice Meter

Corner taps (< 1 inch)

D and D/2 taps ( 2 to 16 inch)

Flange taps (> 16 inch)

Features of Orifice Meter

Design Pressure: No limitation. Limited by DP transmitter

Design Temperature: No limitation. Limited by DP transmitter

Sizes: Maximum size is the pipe size

Flow range: limited only by pipe size.

Fluids/ Applications: Cryogenic / clean gases & liquids/ Steam (saturated/superheated)

MOC: No limitation (Steel/ monel/nickel/ haste alloy)

Accuracy : It varies from ±0.25% to ±0. 5% of actual flow. The accuracy of the DP transmitter varies from ±0.1% to ±0. 3% of full-scale error.

Rangeability is 3:1 to 5:1.

Upstream length/ Downstream straight length is 20 / 5

Advantages of Orifice Meter

Easily installed between flanges.

Fabrication simple and inexpensive.

No limitations on the materials of construction, line size and flow rate

Cost relatively independent of pipe diameter since the cost of DPT is fixed.

No process interruption for the exchange of DP transmitter.

Disadvantages of Orifice Meter

High permanent pressure loss & hence high energy consumption to overcome pressure loss.

Impractical for systems with low static pressure.

Measuring range to about 3:1 to 5:1.

Accuracy decrease with Beta ratios above approximately 0.7.

Subject to damage by water hammer and foreign objects.