A positive displacement flow meter is a cyclic mechanism built to pass a fixed volume of fluid through with every cycle.

Every cycle of the meter’s mechanism displaces a precisely defined (“positive”) quantity of fluid, so that a count of the number of mechanism cycles yields a precise quantity for the total fluid volume passed through the flow meter.

Many positive displacement flow meters are rotary in nature, meaning each shaft revolution represents a certain volume of fluid has passed through the meter.

Some positive displacement flow meters use pistons, bellows, or expandable bags working on an alternating fill/dump cycle to measure discrete fluid quantities.

Positive displacement flow meters have been the traditional choice for residential and commercial natural gas flow and water flow measurement in the United States (a simple application of custody transfer flow measurement, where the fluid being measured is a commodity bought and sold).

The cyclic nature of a positive displacement meter lends itself well to total gas quantity measurement (and not just flow rate), as the mechanism may be coupled to a mechanical counter which is read by utility personnel on a monthly basis.

Positive Displacement Flow Meter

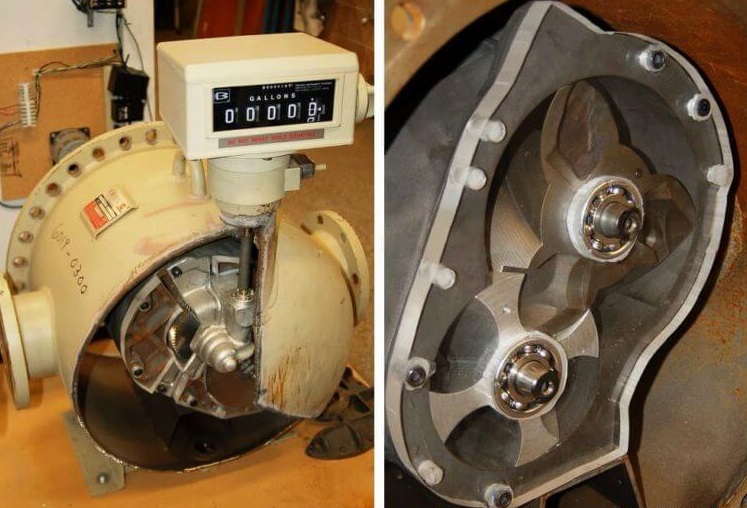

A rotary gas flow meter is shown in the following photograph. Note the odometer-style numerical display on the left-hand end of the meter, totaling gas usage over time:

The left-hand photograph shows the gear mechanism used to convert rotor motion into a visible total readout.

The right-hand photograph shows a close-up of the interlocking rotors (one with three lobes, the other with four slots which those lobes mesh with).

Both the lobes and slots are spiral-shaped, such that fluid passing along the spiral pathways must “push” the lobes out of the slots and cause the rotors to rotate.

So long as there is no leakage between rotor lobes and slots, rotor turns will have a precise relationship to fluid volume passed through the flow meter.

The result is that the meter can measure intermittent flows, very low flow rates, and liquids of almost any viscosity.

The PD meter instantly moves when there is fluid motion, and instantly stops when the fluid motion stops.

This type of measurement is not affected by the liquid’s viscosity, density or the turbulence in the pipe.

All incompressible fluids will occupy the same volume and there is no need to correct the meter’s output to compensate for these factors.

Positive Displacement Meter is a type of flow meter that requires fluid to mechanically displace components in the meter in order for flow measurement.

Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid or gas by dividing the media into fixed, metered volumes (finite increments or volumes of the fluid).

A basic analogy would be holding a bucket below a tap, filling it to a set level, then quickly replacing it with another bucket and timing the rate at which the buckets are filled (or the total number of buckets for the “totalized” flow).

With appropriate pressure and temperature compensation, the mass flow rate can be accurately determined.

These devices consist of a chamber(s) that obstructs the media flow and a rotating or reciprocating mechanism that allows the passage of fixed-volume amounts.

The number of parcels that pass through the chamber determines the media volume.

The rate of revolution or reciprocation determines the flow rate. There are two basic types of positive displacement flow meters. Sensor-only systems or transducers are switch-like devices that provide electronic outputs for processors, controllers, or data acquisition systems.

Positive Displacement Flow Meter Parts Types