Parts of centrifugal pump

This Blog contains basic concepts of Parts of centrifugal pump

- Casing

- Impeller

- Shaft

- Stuffing box

- Mechanical seal

- Bearings

- Spider

- Strainer

Frequently Asked Questions

What are types of Casing? Which casing is more efficient?

What are types of Impeller ? What are their pros & cons?

What is stuffing box's work in Pump?

What is mechanical Seal's work in centrifugal pump?

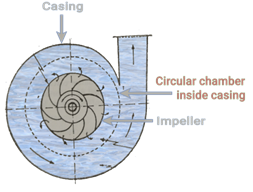

Casing

- Fluid is receiving in casing it is basic curved funnel that increases in area as it approaches the discharge port and

- It converts fluids kinetic energy into pressure

Basic classification of casing

Casing's Initial area has lower space.

Gradually area is increasing which sucks more liquid to impeller eye.

1 Volute casing

Simple volute casing

In this type of casing space between casing and impeller is

lower it produces eddy resistance due to lower initial gap so it requires more

energy motor or higher RPM to develop pressure

Vortex casing

2. Diffuser ring casing

This type casing used in turbine type centrifugal pump there

is guide vans around impeller which are in a ring this type of casing Is

maximum covert fluid kinetic energy into discharge pressure minimum design

losses

[ads id="ads1"]

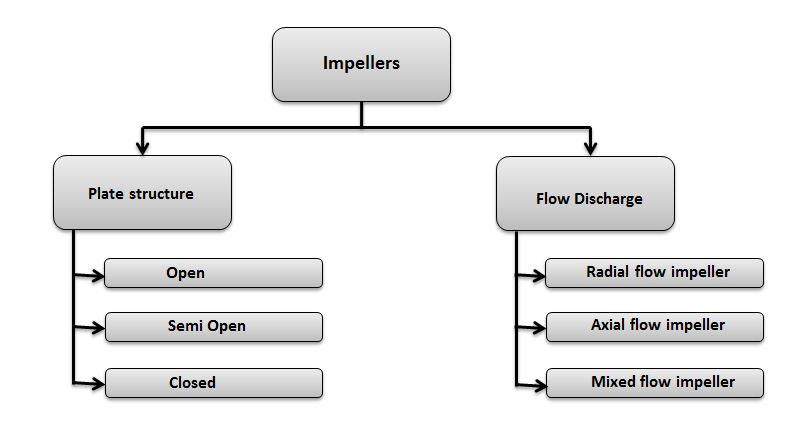

Impeller

Types of impeller

Classification of Impellers

1.

Open impeller

In this type of impeller blades are directly connected to

impeller eye this type of impeller is

used to pump higher viscous liquid like paper pulp & sewage

Uses - Pumping Highly suspended solids containing in liquid

1.

2. Semi open impeller

In this impeller eye and blades is forger on base plate.

This is used to pump liquid with solid particles

Uses - Suspended liquids pumping.

3. Closed impeller

Most efficient impeller wide range of application with

normal clean viscous liquid fluid is also known as shrouded type of impeller

Uses - Clear liquid pumping

Pumping Efficiency : Open impeller < Semi open impeller < Closed Impeller

[ads id="ads1"]

4. Non clogging impeller

Used to pump sewage with paper plastic cloths this has non

chocking design

5. Axial flow impellers

This type of impeller is used to pump two liquids parallel

to mixed in results

Axis flow pattern means Shaft axis and flow direction is parallel.

6. Radial Impeller

It produces radial flow pattern

Radial flow pattern means Shaft axis and flow direction is at 90° Angle

Uses - High head and low flow requirements.

7. Mixed Flow Impeller

Image credit enclosed below

Mixed flow pattern means Shaft axis and flow direction is at 45° - 80° Angle

Used - High flow High head applications.

Impeller suitability and Performance

[ads id="ads1"]

Shaft

Shaft

is used to connect driver to pump impeller to transmit power magnetically

coupled pump also available to avoid use of shaft

Stuffing box

It is used to seal casing with use of packing material and

lantern ring

Mechanical seal

Mechanical seal is used to prevent leakage of under pressure

liquid in to casing

Bearings

It used for smooth operation of pumping generally two

bearings are available

1. Drive side

2. Non drive sideSpider

Spider is used for coupling Drive and pump

Strainer

Strainer is installed in pump suction side after tank isolation valve.

Intension of Strainer installation is to filter pumping liquid and solid impurities & foreign particles kept away from pump for efficient pumping of liquid as well as make pump internals safe.

Non Return Valve - NRV

NRV is installed in pump discharge side before hand isolation valve for back flow prevention to parallel pump.

Another use to install NRV is to prevent priming. For Priming prevention NRV is installed in negative suction pump at suction end which is deep in liquid.

Variable frequency drive - VFD.

Variable frequency drive is installed in those pumps which

- Pumps are exceed flow designed.

- Systems where flow of liquid flow required in significant variations.

Pumps where discharge flow is less required and discharge valve in half close condition loss of energy is there.

Variable frequency drive is installed which control frequency of Voltage of motor.

Reduction in VFD is resulting in Reduction in Pumps motor Rotation RPM reduction.

Reduction in rotation RPM of motor is result in lower power consumption.

Read more about Variable frequency drive - Click here

Watch Centrifugal pump video in Hindi

Read more about "Centrifugal Pump" from Industrial Guide - Click here

Important linksWikipedia

Read on Global Pumps

Read on Introtopump

Photo credits

Mixed flow impellers, Radial Flow Impeller

Buying Links