Cooling Tower Formulas and Calculations contains

- Fan Laws

- Range Approach Formulas

- Heat Rejected by a Cooling Tower

- Refrigeration Tons

- Cooling Tower Tons

- Evaporation Rate

- Water Make-Up Rate

- Cycles of Concentration

- Basic Electrical:

- Water Bleed rate

- AC Line Current in a Single and three Phase Supply

- Liquid to Gas ratio

- Blow down rate ( Draw off)

Fan Laws

The fan laws can be used to predict the performance of a tower with a non-standard motor.

RPM2 = RPM1 (CFM2) / (CFM1)

Static Pressure2 = Static Pressure1 (CFM2/CFM1)2

Horsepower2 = Horsepower1 (CFM2 / CFM1)3

Range Approach Formulas

Range = Entering Water Temperature - Leaving Water Temperature

Approach = Leaving Water Temperature - Ambient Wet-Bulb Temperature

Heat Rejected by a Cooling Tower:

BTUH = (Flow) X (Range) X 500 X (SG) X (SH)

Note: SG = SH = 1 for water

MBH = 1000 BTUH

Refrigeration Tons:

Cooling Tower Tons:

Evaporation Rate = (Flow) x (Range) x 0.001

Cycles of Concentration

Cycle of concentration is parameter through which fresh water make up is determined.

COC = Parameter in cooling tower / Parameter in make up water

Parameters of cooling towers are Silica TDS, Ca, Mg, Conductivity etc.

COC of cooling water is maintained in range of 3 to 7

If COC is higher than 7 then it forms scaling in heat exchangers, jackets, lines. Chemicals are added in cooling towers to preventing scaling and algae formation.

Water Make-Up Rate

The degree to which dissolved solids and other impurities build up in the recirculating water may be

defined as the cycles of concentration. Specifically, cycles of concentration is the ratio of the

concentration of a dissolved solid (for example - chlorides, sulfates, etc.) in the recirculating water to

the concentration of the same material in the make-up water.

Water Make-Up Rate = Bleed Rate + Evaporation Rate

Basic Electrical:

E = I x R

P = I x E

where:

E = voltage (volts)

I = current (amps)

R = resistance (ohms)

P = power (watts)

AC Line Current in a Single Phase Supply

AC Line Current in a Three Phase Supply

Where:

I is the RMS line current in Amps

P is the average output power in Watts

E is the AC line voltage in Volts

PF is the input power factor

EFF is the efficiency of the supply

Steel Gauge Thickness and Weights

Water Quality Guidelines

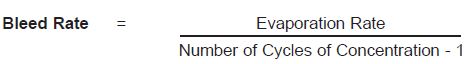

To control the cycles of concentration such that BAC water quality guidelines* are maintained, it will be necessary to “bleed” or “blow down” a small amount of recirculating water from the system. This “bleed” water is replenished with fresh make-up water, thereby limiting the build-up of impurities.

The required continuous bleed rate can be calculated using the following formula:

Evaporation Rate

Method 1

Evaporation Rate = (Flow) x (Range) x 0.001

The evaporation rate can also be estimated as:

• 2 GPM per 1 million BTU/HR of heat rejection

• 3 GPM per 100 tons of refrigeration

Method 2 Heat balance

Heat release by cooling tower

Q = m Cp ΔT = C Cp ΔT

m = Circulation flow m3/h

ΔT = Range of cooling tower; Cooling water inlet( Return) - Outlet temperature.

Other side Evaporated vapour heat possess by atmosphere

Q = m Hv = E Hv

m = Evaporation loss E = Evaporation Rate = (Flow) x (Range) x 0.001

Hv = Latent heat of vaporization = 2260 Kj/kg

Now

Heat release by cooling tower = Evaporated vapour heat possess by atmosphere

C Cp ΔT = E Hv

E = C Cp ΔT / Hv

[ads id="ads1"]

Liquid to Gas ratio

Heat rejected by Cooling tower is absorbed by surrounding atmosphere

Heat absorption through atmosphere is depend humidity

Liquid to gas ratio match by adjusting Fan blade angle and water box loading

Liquid heat release = Atmosphere heat absorb

L ( T1-T2) = G (H2-H1)

L / G = (H2-H1) / ( T1-T2)

Blow down rate ( Draw off)

When cooling water circulates in system then water evaporation will takes place.

Evaporation will increases Total Dissolved Solids - TDS COC will increase .

Controlling of parameters are maintain through drain water and replace with fresh water.

Blow down quantity is calculated through following equation

Blow down = Evaporation loss / ( COC - 1)

[ads id="ads1"]

Windage loss ( Drift loss)

Cooling water loss by air when it circulating in cooling tower and system is called windage loss.

This loss is provided by cooling tower supplier. which can be calculated by following equations

Natural draft

D = [Windage loss x Circulation flow] /100

Windage loss for Natural draft =- 0.3 to 1.0

Windage loss for Induced draft cooling tower = 0.1 - 0.3

Cooling tower with drift eliminator = 0.01

Thanks for reading - Cooling Tower Formulas and Calculations

Naitik Patel

Industrial Guide