Chemical safety measures in storage | Safety blog

|

| Chemical safety measures in storage | Safety blog |

Government statutory provisions are also there for Manufacture storage and import of hazards Chemical rules 1989, Factory act 1948 section 7, 41-B & 41-C, Petroleum, act 1934, Petroleum rules 1976: rule 117 to 131, IS 7445 aacetone, IS4544 ammonia, IS6164 HCl, IS14200 H2O2, IS4262 H2SO4, ITC EHS guidelines, Health and safety at work act 1974 UK, OSH 1974 UK,ILOC170R177, ILO - modular checklist & encylopedia of OHS,

This blog contains- Safety aspects of storages

2. Identification notice

3. Dyke Or Bund

4. Separation distance

5. Vent pipe - Design aspects

6. Overflow line design

7. Tank filling ratio

8. Flameproof electrical fitting should be used in flammable zone flash point below 23'C

9. Earthing & Bonding

10. Protective media

11. Miscellaneous

Interview Questions asked from this blog

1. Which factors should be consider before storage tank design?

2. Which factors are consider for Identification of tank?

2. Which factors are consider for Identification of tank?

3. What is importance of dyke? Which parameters are considered before dyke build?

4. How much distance is required of tank from another tank? Which separation parameters are considered?5. Which parameters are required for vent pipe?

6. How to calculate Maximum tank level filling?

[ads id="ads1"]

Safety aspects

1. Safe Design & maintenance

Design should be considered in

- MOC

- Thickness

- Piping & Connections, Nozzles, Valves,Coating, Jacket, Insulation, cladding, colour coding,

- Dyke / Bund requirement

- Level, Pressure & Temperature measuring devices

- Safety valves, Repture dis Vent line, Scrubber, Flare requirement

- Type of pump requirement.

2. Identification notice

- Notice is required in each storage which mentioning following details

- Chemical language

- Tank capacity & Pressure

- Properties of chemical - SpGr, Vapour density, Boling point, Flesh point, LEL-UEL, TLV, Incompatibility of material

- Emergency control measures, NFPA code

|

| Identification notice |

[ads id="ads1"]

3. Dyke Or BundDyke is a safety contain of tanks build around tank. In the case of leakage of storage tank it restrict to spreading of chemical.

- It is 1.5 times than storage capacity.

- Wall height should not more than 2 meter (1 meter is advisable)

- Individual tank Dyke.

- It has small pit with entire dyke slope toward it with discharge valve.

- Step with railing is required for go inside.& outside.

- Fencing is required for high volatile chemicals - Petroleum, Fuel.

4. Separation distance

Separation distance means keeping safe distance between two tanks and other equipments.Flammable liquids with low to medium pressure - 10- 25 meter

Highly flammable with high pressure - 35 - 50 meter

Boilers - 35 - 50 meter.

Stack with flare - 40 - 75 meter.

5. Vent pipe

Vent valve is provided in tank for -

- Air intake at time pumping liquid.

- Out air at time of loading tanker.

- Exit vapour or gases.

[ads id="ads1"]

- Vent must have mesh or demister pad to keep unwanted object out.

- Easy escape of air.

- Sufficient Diameter as per Chemical stored.

- Flame arrester [ If flash point is below 23'C]

- Breather valve requirement [ For flammable fluid breather valve with Nitrogen connection for blanketing

- Vent cooler - Prevent loss of costly chemical

- Scrubber [ For corrosive fumes ]

- Pressure, Temperature & Level measuring devices.

6. Overflow line design

Overflow line is provided for overflow material with safety.

Overflow line should be -

- Big in size than inlet line.

- Sealing with scrubbing or neutralizing media for fuming liquid.

- Keep 2 - 3 inches above ground for free flow

- If same chemical storage tank near then vent should be in each other.

[ads id="ads1"]

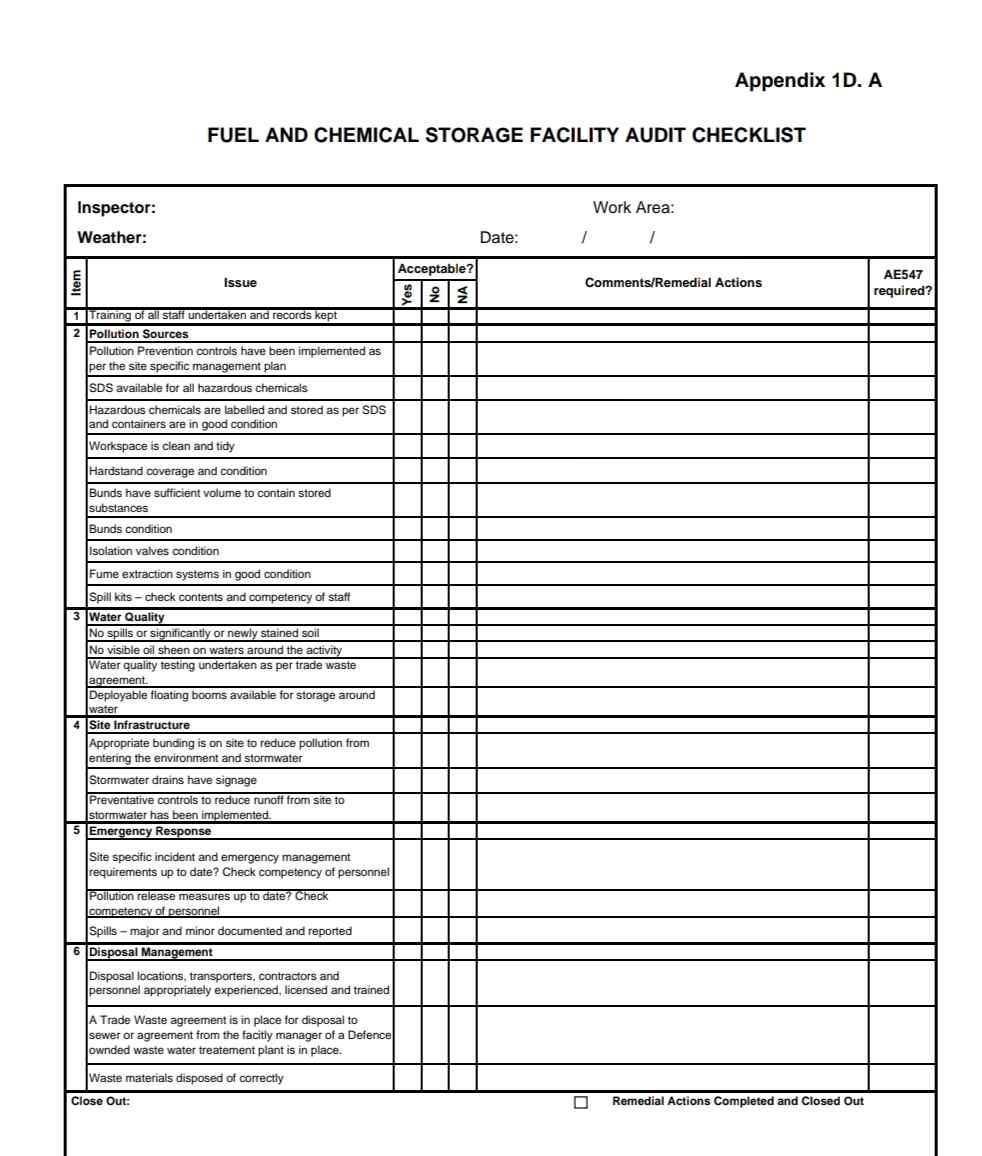

7. Tank filling ratio

It is a ratio of weight of material to weight of water that tank can hold.

Tank should not be filled above its filling ratio

Where C = Cubical expansion of liquid

D15 = Density of liquid at 15'CDr = Density of liquid at TmTm = maximum bulk temperatureTf = Filling temperature

8. Flameproof electrical fitting should be used in flammable zone flash point below 23'C

9. Earthing & Bonding

Tank and piping which is containing flammable fluid must have continuous double earthing with earthing monitoring system.

- Earthing pit must be recharged periodically

- Earthing jumpers must be installed on each flange joint.

- When ever tankers loading / unloading in process double earthing must be provided.

[ads id="ads1"]

Chemicals must be protected against non compatible chemicals and conditions

- Low boiling point tanks should be underground

- Polymerization chemicals must be stored in water spray

- Chemicals with high melting point should be stored in hot storage vessels

- Sodium metal must store in kerosene

- Flammable fluids are stored in nitrogen blanketing

11. Labeling

Labelling is the practice of clearly marking every chemical container, drum, tank, and storage area with correct safety and identity information so that users can identify.

Labelling importance

- Prevents wrong chemical use

- Avoids mixing of incompatible materials

- Reduces fire, explosion, and exposure risks

- Supports quick emergency response

- Ensures legal and regulatory compliance

- Helps in inventory and expiry control

Chemical Label Must Contain

1. Chemical Name: Full name (no short forms or local names), Trade name + scientific name if applicable

2. Hazard Classification: Flammable, Toxic, Corrosive, Oxidizer, Explosive, etc.

3. GHS Pictograms: Standard hazard symbols for quick visual warning

4. Signal Word: Danger (high risk), Warning (moderate risk)

5. Hazard Statements: Short description of risk

Example: Causes skin burns, Highly flammable liquid

6. Precautionary Statements: Basic safe handling and storage instructions

7. Batch Number: Required for traceability (especially in pharma)

8. Manufacturing Date & Expiry Date: Mandatory for stability and safety control

9. Storage Conditions: Temperature, light protection, moisture sensitivity, etc.

10. Handling Instructions: Use in fume hood, avoid sparks, keep container closed, etc.

11. Emergency Information: First-aid summary, Spill or fire response type

12. Supplier Details: Name, address, and emergency contact

Storage Area Labelling

Storage rooms must be labeled by hazard type

- Flammable Store

- Acid Store

- Toxic Material Store

- Oxidizer Store

Tanks and pipelines must show:

- Chemical name

- Flow direction

- Hazard color code

Color Coding (Common Practice)

Red → Flammable

Yellow → Reactive / Oxidizer

Blue → Health hazard

White → Corrosive

Green → Non-hazard / Safe material

(Plant-specific codes must be displayed)

Labelling Rules

- Labels must be clear, readable, and permanent

- No handwritten labels for hazardous chemicals

- Damaged or faded labels must be replaced immediately

- Secondary containers must also be labeled

- No container should remain unlabeled

Emergency Value of Proper Labelling

- Helps firefighters choose correct extinguisher

- Guides medical team in treatment

- Prevents wrong spill response

- Saves time during accidents

Segregation of Chemicals in Storage Safety

Segregation of chemicals means storing incompatible chemicals separately so they do not react with each other if leaked, mixed, or exposed accidentally. This prevents fires, explosions, toxic gas release, and product contamination.

Why Segregation is Necessary

- Prevents dangerous chemical reactions

- Reduces fire and explosion risks

- Avoids toxic gas formation

- Protects workers and equipment

- Supports safe emergency response

Common Dangerous Combinations

- Acids + Bases

- Oxidizers + Flammables

- Water-reactive + Moisture

- Cyanides + Acids

- Peroxides + Metals

- Ammonia + Chlorine

- PPEs and Fire fighting equipments must be used near storage

- Safe loading /unloading processes & checklists

- Chemical detection system Fire detection system and sprinkler system should be installed in fire prone area

- Tanker loading MOC compatibility must be checked

[ads id="ads1"]