1. Introduction to Static Electricity

Static electricity is a common but critical hazard in chemical, pharmaceutical, and petrochemical industries.

Many processes involve flammable liquids, vapors, gases, and fine powders.

Uncontrolled static charge can act as an ignition source, leading to fire or explosion during routine operations like filling, transfer, mixing, or packaging.

1.1 Meaning of Static Electricity

Static electricity is the buildup of electric charge on the surface of a material caused by an imbalance between positive and negative charges.

It is mainly generated when materials come into contact and then separate, such as liquid flowing in pipes, powders moving in equipment, or people walking on insulating floors.

The charge remains stored until it discharges suddenly, which may produce a spark capable of igniting flammable atmospheres.

1.2 Nature of Static Charge

- Static charge is stationary and does not flow continuously like current electricity

- It accumulates more easily on non-conductive materials such as plastics, rubber, and dry powders

- The charge can build up silently and discharge without warning

- Discharge energy depends on the amount of charge, material, and grounding condition

- In hazardous areas, even low-energy static discharge can ignite vapors, gases, or dust clouds

2. Generation of Static Electricity

In industries, static electricity is mainly generated during material movement, contact, and separation.

2.1 Triboelectric Effect

It occurs when two different materials come into contact and then separate, causing electrons to transfer from one surface to another.

This happens during

- Powder mixing

- Tablet coating

- Bag filling

- Conveyor movement

- Liquids splash

- Agitate in tanks

Insulating materials like plastics and dry powders accumulate higher static charge, increasing fire and explosion risk.

2.2 Induction static electricity

Induction is the generation of static charge without direct contact.

When a charged object comes close to a conductive object, it causes a redistribution of electrical charges on the surface.

In process plants, induction can occur when grounded and ungrounded equipment is placed near charged pipelines, containers, or vessels.

If proper grounding is missing, the induced charge can discharge suddenly as a spark.

2.3 Flow Electrification Static electricity

Flow electrification occurs when liquids, gases, or powders move at high velocity through pipes, hoses, filters, or nozzles.

The friction between the flowing material and the equipment surface generates static charge.

This is common during solvent transfer, fuel loading, filtration, spray drying, and pneumatic conveying.

Low-conductivity liquids and high flow rates significantly increase static charge buildup, making flow electrification a major ignition hazard in hazardous areas.

[ads id="ads1"]

2.4 Where do charges come from?

3. Materials and Static Electricity

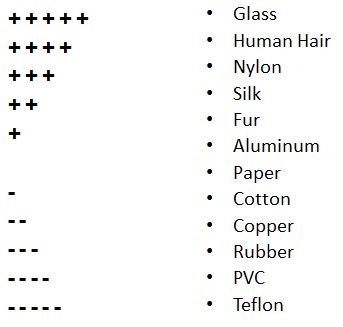

In chemical, pharmaceutical, and petrochemical industries, the ability of a material to conduct or resist electrical charge directly affects static electricity hazards.

Material selection plays a critical role in controlling static charge buildup and preventing ignition in hazardous areas.

3.1 Conductive Materials

Conductive materials allow static charge to flow freely and safely dissipate to earth when properly grounded.

Metals such as steel, copper, aluminum, and stainless steel are commonly used for tanks, pipelines, reactors, and equipment because they reduce static charge accumulation.

When these materials are effectively earthed and bonded, the risk of spark discharge is significantly minimized.

3.2 Non-Conductive (Insulating) Materials

Non-conductive or insulating materials resist the flow of electric charge, causing static electricity to accumulate on their surfaces.

Common examples include plastics, rubber, glass, and certain coatings.

In industrial operations, insulating materials used in hoses, containers, liners, and packaging can store high static charge and release it suddenly, creating ignition risk in flammable atmospheres.

3.3 Static Accumulating Materials

Static accumulating materials are those with high electrical resistance that easily build up and retain static charge.

These include dry powders, plastic films, synthetic fabrics, and non-conductive liquids.

During powder handling, solvent transfer, and packaging operations, these materials can generate and hold significant static charge, increasing the possibility of electrostatic discharge, fire, or explosion if proper controls are not in place.

3.4 Static Discharge

How does a positively charged rod attract a neutral object?

3.5 Grounding

4. Static Electricity in Industrial Operations

In chemical, pharmaceutical, and petrochemical industries, static electricity is commonly generated during routine processing operations.

Movement, transfer, and handling of liquids, powders, gases, and vapors can create static charge, which may become an ignition source in flammable or explosive atmospheres if not properly controlled.

4.1 Liquid Handling Operations

Static electricity is generated during liquid transfer, filling, draining, mixing, spraying, and filtration.

High flow velocity, splashing, and turbulent flow increase static charge buildup, especially in low-conductivity liquids such as solvents, fuels, and hydrocarbons.

Static discharge during tank filling, drum loading, or tanker operations can ignite flammable vapors present above the liquid surface.

4.2 Powder and Solid Handling

Powder and solid handling operations such as conveying, blending, drying, sieving, milling, and filling generate static charge due to continuous contact and separation between particles and equipment surfaces.

Fine and dry powders accumulate high static charge and can form explosive dust clouds.

Electrostatic discharge during these operations can trigger dust fires or explosions in processing and packaging areas.

4.3 Gas and Vapor Flow

Static electricity can be generated when gases or vapors flow at high speed through pipes, vents, valves, and nozzles.

Although gases generally carry lower charge than liquids, high velocity, pressure changes, and the presence of particles or droplets can increase static generation.

In petrochemical and solvent-handling systems, static discharge in gas and vapor lines can ignite flammable mixtures within confined spaces.

5. Hazards of Static Electricity

In chemical, pharmaceutical, and petrochemical industries, static electricity is a serious safety hazard because even a small electrostatic discharge can act as an ignition source.

The presence of flammable liquids, vapors, gases, and dust makes static-related incidents highly dangerous.

5.1 Ignition Hazard

Static electricity can discharge as a spark, brush, or corona, releasing enough energy to ignite flammable vapors, gases, or dust clouds.

This ignition hazard is common during solvent transfer, tank filling, powder handling, and packaging operations.

In hazardous areas, static discharge can occur without warning and initiate combustion instantly.

5.2 Fire and Explosion Risk

Electrostatic discharge can cause fires and explosions when it ignites flammable atmospheres within vessels, pipelines, reactors, or processing rooms.

Vapors above liquid surfaces and suspended dust clouds are particularly sensitive to static ignition. Such incidents can result in equipment damage, plant shutdown, and major loss to life and property.

5.3 Personnel Shock Hazard

Accumulated static charge on personnel can discharge when touching grounded or conductive objects, causing electric shock.

While usually not fatal, the shock can lead to startle reactions, loss of balance, or falls, increasing the risk of secondary accidents, especially in elevated or confined work areas.

6. Types of Static Electricity Discharge

In chemical, pharmaceutical, and petrochemical industries, static electricity becomes hazardous when accumulated charge releases suddenly as a discharge.

Different types of electrostatic discharge have different ignition potentials, especially in flammable and explosive atmospheres.

6.1 Spark Discharge

Spark discharge is a sudden and visible release of static charge between two objects at different electrical potentials.

It usually occurs between conductive objects or between a charged object and a grounded surface.

In industrial operations such as tank filling, drum transfer, and tanker loading, spark discharge has high energy and can easily ignite flammable vapors, gases, or dust clouds, making it the most dangerous type of static discharge.

6.2 Brush Discharge

Brush discharge occurs from charged non-conductive or insulating surfaces to nearby conductive objects.

It is less intense than a spark but can still release sufficient energy to ignite flammable gases and vapors.

Brush discharge is common on plastic containers, liners, coatings, and flexible hoses used in chemical and pharmaceutical processing, especially in low-humidity conditions.

6.3 Corona Discharge

Corona discharge is a low-energy discharge that occurs around sharp edges or pointed conductors when the electric field becomes strong.

It may appear as a faint glow or hissing sound. In most industrial situations, corona discharge has low ignition capability, but in sensitive flammable atmospheres, it can still contribute to ignition risk and should not be ignored.

7. Factors Affecting Static Charge Accumulation

7.1 Humidity

- Low humidity increases static charge buildup

- Dry air reduces natural charge dissipation

- Common risk in air-conditioned pharmaceutical areas

- Higher humidity helps reduce static electricity

7.2 Flow Velocity

- High flow speed increases friction and charge generation

- Fast pumping, spraying, and conveying raise static risk

- Low-conductivity liquids generate higher static charge

- Fine powders accumulate charge rapidly at high velocity

7.3 Turbulence and Surface Area

- Turbulent flow increases static generation

- Splashing and agitation raise charge buildup

- Bends, filters, and nozzles increase friction

- Fine powders and sprays have high surface area

8. Static Electricity Control Methods

8.1 Earthing (Grounding)

- Provides safe path for charge dissipation

- Prevents charge accumulation on equipment

- Required for tanks, pipelines, drums, and tankers

- Reduces risk of spark discharge

8.2 Bonding

- Connects conductive equipment together

- Equalizes electrical potential between objects

- Prevents spark during transfer operations

- Essential during liquid filling and loading

8.3 Use of Conductive and Anti-Static Equipment

- Conductive hoses and containers reduce charge buildup

- Anti-static flooring and tools control discharge

- Suitable for hazardous and classified areas

- Minimizes ignition risk in flammable atmospheres

8.4 Flow Rate Control

- Lower flow rate reduces friction

- Slow initial filling limits charge generation

- Avoids splashing and turbulence

- Improves safety during transfer operations

9. Personal Protective Measures

9.1 Anti-Static Clothing

Anti-static clothing is designed to prevent the buildup of static charge on the human body.

In chemical, pharmaceutical, and petrochemical industries, such clothing is made from conductive or static-dissipative fibers that allow charge to safely disperse.

It reduces the risk of electrostatic discharge during solvent handling, powder processing, and work in hazardous areas.

9.2 Anti-Static Footwear

Anti-static footwear provides a controlled path for static charge to flow from the body to the ground through conductive flooring.

It prevents charge accumulation on personnel while walking or working near flammable materials.

Proper anti-static footwear is essential in classified areas to reduce spark risk caused by human movement.

9.3 Personnel Earthing Systems

Personnel earthing systems ensure continuous grounding of workers by safely dissipating static charge from the body.

These systems include earthing straps, conductive floors, and grounding points used during critical operations.

They are especially important during drum filling, tanker loading, and powder handling where human-induced static discharge can act as an ignition source.

10. Static Electricity in Hazardous Areas

10.1 Classified Areas

Classified areas are locations in chemical, pharmaceutical, and petrochemical industries where flammable gases, vapors, liquids, or combustible dusts may be present during normal or abnormal operations.

In these areas, static electricity is a critical ignition hazard because even a small electrostatic discharge can ignite the atmosphere.

Typical classified areas include solvent handling sections, reactors, filling and packaging areas, powder processing rooms, and tanker loading zones.

10.2 Equipment Selection for Hazardous Zones

Equipment used in hazardous zones must be selected to minimize static charge buildup and prevent electrostatic discharge.

Conductive or anti-static materials should be used for tanks, pipelines, hoses, containers, and tools. Proper earthing and bonding of all equipment is essential to safely dissipate static charge.

Using approved and suitable equipment for hazardous areas significantly reduces the risk of fire and explosion.

11. Detection and Monitoring

11.1 Static Charge Detection

- Used to identify buildup of static electricity on equipment, pipelines, containers, and materials

- Helps detect unsafe charge levels before electrostatic discharge occurs

- Common in solvent transfer, powder handling, and tanker loading operations

- Enables early control actions to prevent ignition in flammable atmospheres

11.2 Earthing Integrity Monitoring

- Ensures earthing and bonding connections are continuously effective

- Detects loose, broken, or high-resistance grounding connections

- Critical during drum filling, tanker loading, and batch processing

- Prevents spark discharge caused by loss of proper grounding

12. Static Electricity Related Incidents

12.1 Typical Incident Scenarios

Static electricity related incidents in chemical, pharmaceutical, and petrochemical industries commonly occur during tank and drum filling, tanker loading and unloading, solvent transfer, powder conveying, blending, drying, and packaging operations.

Static discharge can ignite flammable vapors above liquid surfaces or combustible dust clouds formed during powder handling, leading to fire or explosion within equipment, rooms, or confined spaces.

12.2 Root Causes of Static-Related Accidents

Root causes include inadequate earthing and bonding, use of non-conductive or insulating materials, high transfer velocities, low humidity conditions, and poor equipment design.

Failure to follow safe operating procedures, damaged grounding connections, and lack of static control measures also contribute to static electricity accidents in hazardous industrial environments.

13. Legal and Safety Requirements

13.1 Applicable Safety Standards

Chemical, pharmaceutical, and petrochemical industries must follow recognized safety standards to control static electricity hazards. These standards require proper earthing and bonding of equipment, use of anti-static materials, control of ignition sources in hazardous areas, and regular inspection of grounding systems. Compliance ensures safe handling of flammable liquids, gases, vapors, and combustible dusts and reduces the risk of fire and explosion.

13.2 Employer and Employee Responsibilities

Employers are responsible for identifying static electricity hazards, implementing control measures, maintaining earthing systems, and providing training and suitable personal protective equipment. Employees must follow safe operating procedures, use approved anti-static clothing and footwear, ensure grounding connections are in place before operations, and report damaged or unsafe conditions related to static electricity control.

14. Key Safety Practices

14.1 Do’s

- Ensure proper earthing and bonding of all equipment before starting operations

- Use conductive or anti-static hoses, containers, and tools in hazardous areas

- Wear approved anti-static clothing and footwear

- Maintain controlled flow rates during liquid and powder transfer

- Regularly inspect and test earthing and bonding connections

- Follow approved operating procedures in classified areas

- Ensure all tanks, drums, pipelines, reactors, and transfer equipment are properly earthed and bonded

- Verify earthing continuity before starting liquid transfer, drum filling, or tanker loading

- Use conductive or anti-static hoses, containers, liners, and tools in hazardous areas

- Wear approved anti-static clothing, footwear, and PPE suitable for classified zones

- Maintain slow and controlled flow rates, especially during initial filling

- Minimize splashing, free fall, and turbulence during liquid and powder handling

- Keep humidity at safe levels where feasible to reduce static buildup

- Use certified equipment designed for hazardous and explosive atmospheres

- Conduct regular inspection and testing of earthing and bonding systems

- Follow standard operating procedures and permit systems for static-sensitive tasks

- Ensure earthing and bonding of all fixed and mobile equipment before use

- Confirm grounding continuity using approved indicators or monitoring systems

- Use only conductive or anti-static drums, containers, IBCs, and packaging

- Wear certified anti-static clothing, footwear, and PPE at all times in hazardous areas

- Start liquid filling at low speed and increase gradually after wetting the line

- Keep liquid outlets below the liquid surface during filling to avoid splashing

- Maintain clean equipment to prevent dust accumulation and static buildup

- Control powder handling using enclosed systems where possible

- Maintain safe humidity levels in processing and storage areas

- Use conductive flooring and personnel earthing systems where required

- Follow permit-to-work systems for transfer, maintenance, and cleaning activities

- Train workers regularly on static electricity hazards and controls

14.2 Don’ts

- Do not operate equipment with missing or damaged earthing connections

- Do not use plastic, rubber, or insulating tools in classified areas unless approved

- Do not allow free fall of liquids or powders from height

- Do not exceed recommended flow rates for flammable materials

- Do not wear synthetic garments that can generate static charge

- Do not ignore alarms from earthing or grounding monitoring devices

- Do not perform manual handling of powders without static control measures

- Do not allow dust layers to accumulate on floors, equipment, or structures

- Do not modify grounding systems without authorization

- Do not assume static risk is eliminated by visual checks alone

- Do not start transfer operations without confirming proper earthing and bonding

- Do not use non-conductive or damaged hoses, containers, or equipment in hazardous areas

- Do not allow high-speed filling or uncontrolled powder discharge

- Do not wear synthetic or non-approved clothing in static-sensitive zones

- Do not ignore loose, broken, or corroded grounding connections

- Do not bypass safety interlocks or earthing monitoring systems

- Do not perform hot work or maintenance in flammable areas without clearance

- Do not store or handle flammable materials near ungrounded equipment

- Do not assume static risk is low during normal or routine operations

- Do not transfer flammable liquids or powders without proper grounding

- Do not use plastic or insulating containers in hazardous zones unless approved

- Do not allow splashing, free fall, or high turbulence during filling operations

- Do not bypass or remove earthing and bonding connections

- Do not work in hazardous areas with damaged anti-static PPE

Most Asked interview Questions

-

What is static electricity?

Static electricity is the accumulation of electrical charge on the surface of a material due to imbalance between positive and negative charges. It remains stored until it discharges suddenly, which can act as an ignition source in flammable atmospheres. -

How is static electricity generated in industrial operations?

Static electricity is generated by contact and separation of materials, flow of liquids or powders, friction, splashing, and high-velocity movement in pipes, hoses, and conveyors commonly used in chemical and pharmaceutical processes. -

What is the triboelectric effect?

The triboelectric effect is the generation of static charge when two different materials come into contact and then separate, causing transfer of electrons from one material to another. This is common during powder mixing, conveying, and handling of plastic or rubber materials. -

What is flow electrification?

Flow electrification is static charge generation caused by the movement of liquids, gases, or powders through pipelines, filters, or hoses. It increases with higher flow velocity, turbulence, and low-conductivity liquids such as solvents and hydrocarbons. -

Why are low-conductivity liquids more prone to static charge buildup?

Low-conductivity liquids cannot easily dissipate electrical charge, so static electricity generated during flow remains accumulated. This stored charge can discharge suddenly and ignite flammable vapors. -

What is the difference between earthing and bonding?

Earthing is the connection of equipment to the ground to safely discharge static electricity. Bonding is the connection between two or more conductive objects to keep them at the same electrical potential and prevent spark formation. -

Why is earthing critical during tanker loading and unloading?

Earthing is critical because large volumes of flammable liquids flow at high speed, generating static charge. Proper earthing safely dissipates this charge and prevents spark discharge that could ignite vapors. -

What are the common sources of static electricity in process plants?

Common sources include liquid transfer, drum filling, tanker loading, powder conveying, mixing, filtration, spraying, pneumatic transport, and movement of personnel on insulating floors. -

How does humidity affect static electricity?

Low humidity increases static charge buildup because dry air reduces charge leakage. Higher humidity helps dissipate static charge naturally and lowers ignition risk. -

What types of static electricity discharge exist?

The main types are spark discharge, brush discharge, and corona discharge. Spark discharge has the highest ignition energy, brush discharge occurs from insulating surfaces, and corona discharge is low energy but still hazardous in sensitive areas.

-

Which static discharge is most dangerous and why?

Spark discharge is the most dangerous because it releases high energy in a very short time. This energy is sufficient to ignite flammable gases, vapors, and dust clouds commonly present in chemical and petrochemical plants. -

Can static electricity ignite flammable vapors or dust? Explain how.

Yes, static electricity can ignite flammable vapors or dust when accumulated charge discharges as a spark. The discharge provides ignition energy higher than the minimum ignition energy of the vapor or dust cloud. -

Why are plastic containers risky in hazardous areas?

Plastic containers are insulating materials that allow static charge to build up and remain stored. When the charge discharges suddenly, it can create an ignition source in flammable atmospheres. -

What materials are considered conductive, insulating, and static accumulating?

Conductive materials allow charge to flow easily, such as metals. Insulating materials resist charge flow, such as plastic and rubber. Static accumulating materials easily build and retain charge, such as dry powders, plastic films, and low-conductivity liquids. -

How does flow velocity influence static charge generation?

Higher flow velocity increases friction and turbulence, which generates more static charge. Faster transfer rates directly increase the risk of electrostatic discharge. -

Why is slow initial filling recommended for flammable liquids?

Slow initial filling reduces turbulence and splashing, limits static charge generation, and allows the system to become safely wetted before increasing flow rate. -

What static hazards are associated with powder handling?

Powder handling generates static due to particle movement and friction. Fine powders can accumulate high charge and form combustible dust clouds that may ignite from electrostatic discharge. -

What is brush discharge and where does it commonly occur?

Brush discharge is a static discharge from a charged insulating surface to a nearby conductor. It commonly occurs on plastic containers, liners, hoses, and coated equipment. -

What PPE is required to control static electricity for personnel?

Anti-static clothing, anti-static footwear, and suitable personal earthing systems are required to prevent charge buildup on the human body. -

Why is anti-static footwear important in hazardous areas?

Anti-static footwear allows static charge to safely flow from the body to the ground through conductive flooring, preventing spark discharge caused by human movement.

-

What is personnel earthing and where is it used?

Personnel earthing is a method of safely dissipating static charge from the human body to ground. It is used during drum filling, tanker loading, powder handling, and operations where human contact with flammable materials is involved. -

How do classified areas relate to static electricity risk?

Classified areas contain flammable gases, vapors, or combustible dust. In these areas, even a small static discharge can act as an ignition source, making static electricity control critical. -

What equipment features help control static electricity?

Equipment made of conductive or anti-static materials, proper earthing and bonding points, smooth internal surfaces, and controlled flow designs help reduce static charge buildup. -

What are common causes of static electricity-related accidents?

Common causes include poor or missing earthing and bonding, use of insulating materials, high flow rates, low humidity, damaged grounding connections, and unsafe operating practices. -

How can static electricity be detected or monitored?

Static electricity can be detected using charge indicators, static field meters, and earthing integrity monitoring systems that confirm effective grounding. -

What checks should be done before starting solvent transfer?

Ensure earthing and bonding connections are in place, verify grounding continuity, confirm approved equipment use, and set controlled flow rate before starting transfer. -

Why is bonding required between drums and filling nozzles?

Bonding eliminates potential difference between the drum and nozzle, preventing spark discharge during liquid transfer. -

Can static electricity be eliminated completely?

Static electricity cannot be completely eliminated, but it can be effectively controlled through proper design, earthing, bonding, and safe operating practices. -

What safety practices reduce static electricity risk in plants?

Proper earthing and bonding, controlled flow rates, use of anti-static equipment and PPE, good housekeeping, and adherence to procedures reduce static risks. -

What regulatory or safety requirements address static electricity hazards?

Safety regulations require risk assessment, control of ignition sources, proper grounding systems, use of approved equipment, and worker training to manage static electricity hazards.