Open loop

Controller is not using feedback value called Open loop

Open loop ExampleReactor start filling with 10000 liter water but it partially filled already. Addition of water will not stop whether it overflows .

Close loop

Feedback is utilized to maintain process parameter this loop called close loop

Difference between Set value and Actual value is called error. This error value is giving feedback to PID loop.

This PID Loop gives correction in Output to controller.

Example

Control valve in steam line maintain 10kg/cm2 at 50% valve Opening.

If line pressure dropped 8 kg/cm2 then valve opening will be increased up to 70%.

If line pressure raised 12 kg/cm2 then valve opening will be reduced up to 30%.

( These are approximate values)

When pressure increasing sensor gives feedback to controller, controller proceed difference between Set point and Actual value to controller and gives feedback according to control valve.

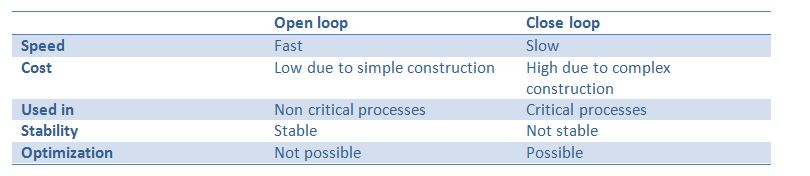

Difference between Open loop and Close loop

1. Open loop has simple in construction so it has good speed

2. Open loop is simple in construction so it is economic. Close loop has sensors, valves or other controllers which increases cost of installation, operation and maintenance cost.

3. Close loop is used in critical, continuous processes. Open loop is used in non critical processes.

4. Process in which level, pressure, temperature maintaining through PID loop behaves oscillatory so Close loop is not stable. while open loop has no feedback system so it is stable