Centrifugal pump comparison Horizontal vs Vertical

Industrial centrifugal pumps are two types as per arrangement

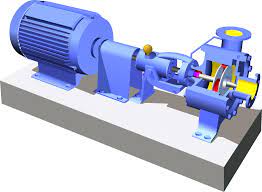

1. Horizontal Centrifugal Pump

2. Vertical Centrifugal Pump

Both have unique usage and applications. We will compare both types in details in each aspect in following

- Defining Parameter

- Foundation area

- Installation requirement

- Maintenance

- Coupling and Alignment

- Radial load [Thrust load]

- Operational range

1. Defining Parameter

Horizontal Centrifugal Pump:

Horizontal pump's shaft is horizontal in Position and laid on ground in operation.

Vertical Centrifugal pump:

Vertical Centrifugal pump shaft oriented vertical. This pumps are generally in Standing or Hanging positions.

[ads id="ads1"]

2. Foundation area required

Horizontal Centrifugal Pump:

High wide foundation area required but less height is required.

Vertical Centrifugal pump:

Less foundation area required but high height is required.

3. Installation requirement

Horizontal Centrifugal Pump:

- Low head room required

- Piping is more complicated.

- Precious adjustment

- Pump alignment is necessory

- Motor mounting space is required

- High head room is required.

- Additional pit barrel is required

Horizontal Centrifugal Pump:

Easy and quick maintenance.

Parts of horizontal pumps are interchangeable.

Parts are less costly and easily available

Vertical Centrifugal pump: